This is a companion piece to Virtual Commissioning with Rockwell Automation, created for those who use tools from B&R. Be sure to choose the article that’s relevant to your automation tools!

How does it look to implement virtual commissioning with B&R Industrial Automation tools?

Depending on the tools you use for machine design, the specific ways to adopt virtual commissioning will look different. As a technology, virtual commissioning relies on an integrated connection between the digital twin and the control design environment. In this post, we’ll focus on virtual commissioning with B&R tools, and the video below shows the key steps involved.

As you see in the video above, the general workflow for virtual commissioning with B&R customers involves a few different tools to bring the digital twin together with your PLC design environment. Let’s break it down into a few steps.

Creating the Digital Twin

The foundation of machine-level virtual commissioning is a digital twin that can simulate the performance of that machine as it moves through various motion profiles. The digital twin seen here, created in MapleSim, models the key aspects of an injection molding machine. The model includes components from various domains (mechanical, hydraulic, etc…) that are contained in the same simulation environment.

When the digital twin is created, it is exported as a Functional Mock-up Unit (FMU) – a version of the model that can be imported by other tools. In this case, we’re using a B&R tool called Automation Studio.

Connecting the Digital Twin to the PLC Design Tools

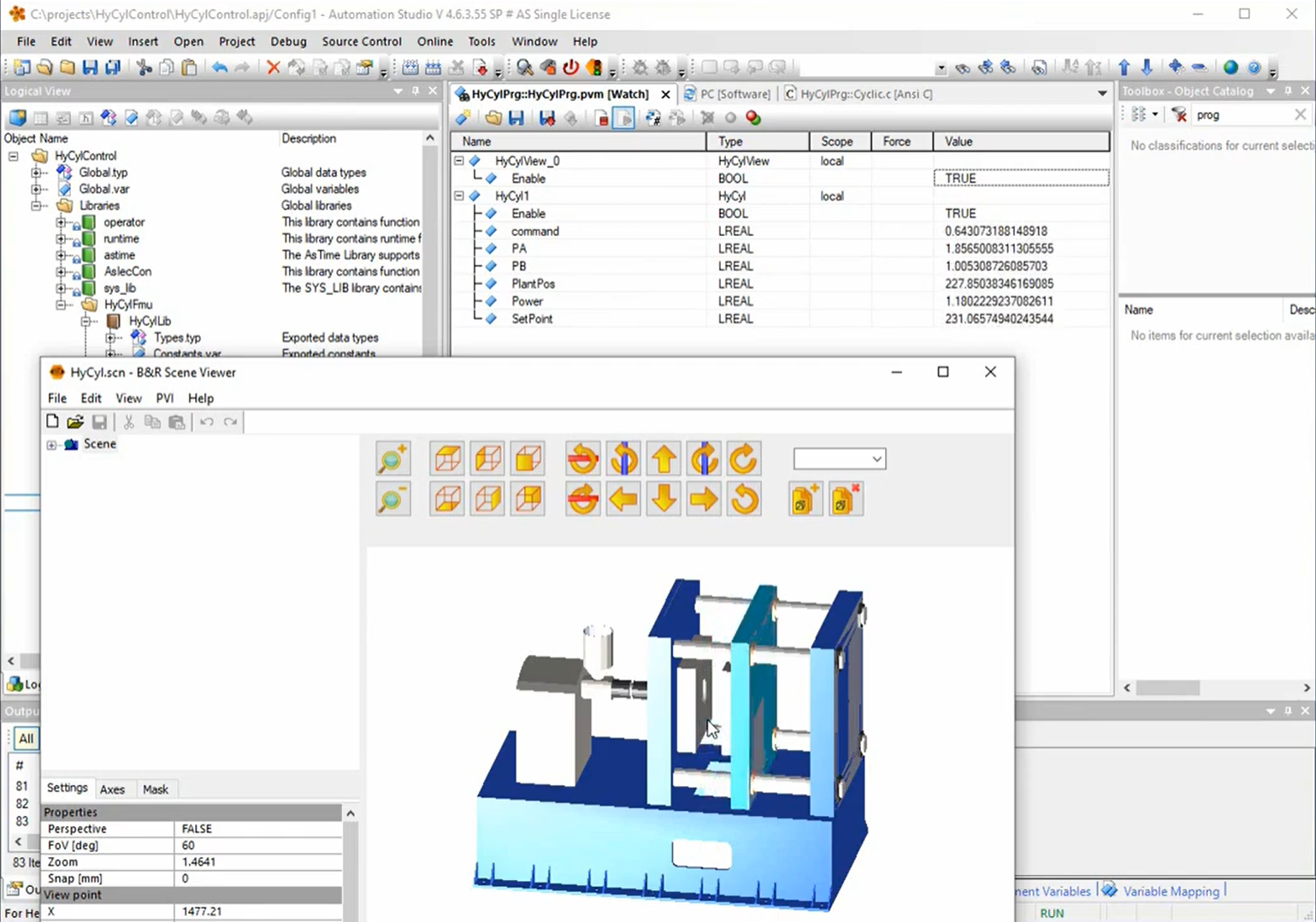

As you saw in the video, the Digital Twin, exported as an FMU, is loaded into B&R Automation Studio. From there, you’ll be able to access your FMU inputs and outputs, and you can connect this FMU to the control code you’ve developed in Automation Studio.

Test Your Control Code Against the Digital Twin

Now, you’re ready for virtual commissioning with B&R Automation Studio. In the video, Automation Studio is being used to now test control strategies against the digital twin that’s been imported. Beyond that, you’ll also see B&R Scene Viewer is running, which gives immediate feedback in the form of 3-D model visualizations. With both of these tools together, you’ll be able to make adjustments to your model, and quickly see how the machine performance is impacted.

Check out the video above for the full demonstration.